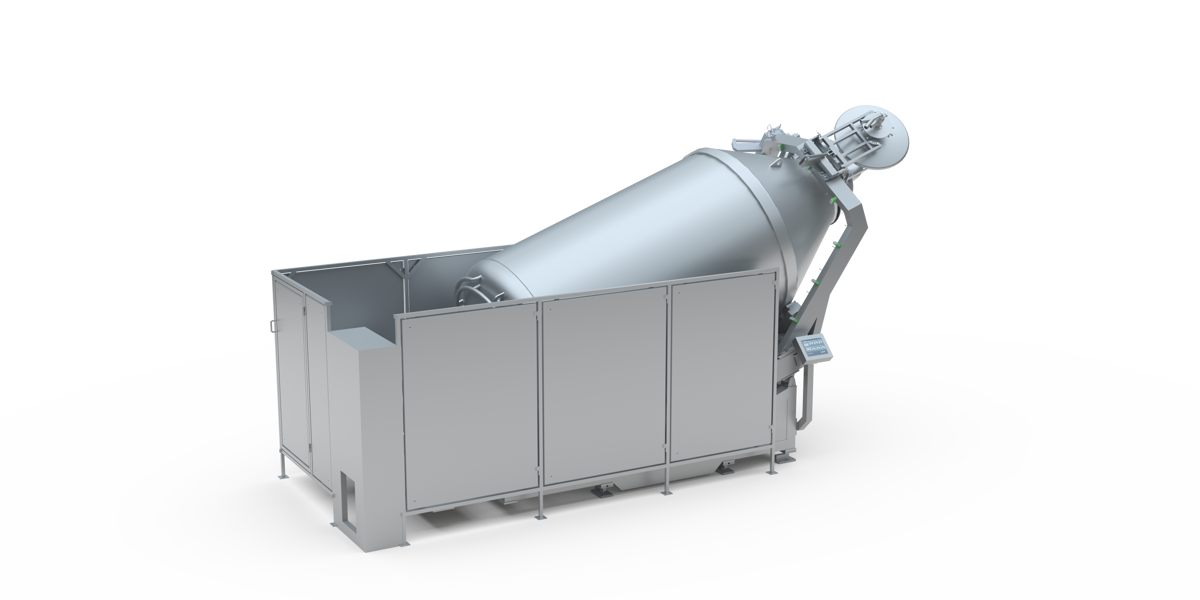

MA12000

Danfotech Massage System Type MA12000

The unique "carrier shape " of the MA12000's internal fins, coupled with their angle and the vacuum system (whether continuous or pulsed), initiates an osmotic massage. This massage ensures a consistent absorption of ingredients into the meat, even during brief massaging periods. As a result, this minimizes product strain and the subsequent temperature increase.

- The flexibility of the massaging system enables the attainment of optimal processing outcomes for various types of meat—whether they're whole or in pieces, and whether they're treated with injected solutions or dry salt.

- This reduces the stress of the product and its consequent increment of temperature.

Programming parameters

The software allows one to memorize 32 recipes, each one consisting of 4 processing phases and customizable with the following parameters:

- Rotation speed

- Rotation direction: clockwise/counterclockwise

- Time of massage

- Time of pause

- Vacuum time

- Pulsating vacuum/ continuous vacuum

- Further to this the software also manages the:

- Alarm system and self-diagnosis of malfunctions

- Maintenance guide

Loading and unloading

The machine can be loaded:

- By tilting-lifter for 200/300 L meat trolleys or bigger bins

- By conveyor belts

-

By vacuum system

- Requires a hopper or a bin

- The unloading is obtained by the gradual and controlled tilting of the drum, avoiding the sudden fall of the product and loss of liquid

Cleaning and sanitizing

- The maximum tilt angle reached by the tumbler permits the liquids to flow away very well, which allows an effective washing avoiding stagnation of residuals

- The internal surface of the drum is easily accessible from the exterior for inspection, cleaning, and microbiological sanitation

- The quick-release protection panels allow the operator to access the machine within a few seconds for clearing and routine maintenance

Optional equipment

- Automatic opening of lid either with electrical or pneumatic opening

- Refrigerated -heated jackets and wings with automatic controls via HMI

- Thermal probe for product temperature control

- Integrated load cells

- Polishing of the internal surface of the drum

Contact

Size specifications

Technical specifications

| Model option | MA12000 |

| Volume (liter/cubic feet) | 12000/424 |

| Degree of admission approx. 60% (kg/lb.) | 7200/15873 |

| Basic Dimensions (vary with options) | |

| Length (mm/inch) (A) | 5900/232 |

| Length (mm/inch) (B) | 4300/169 |

| Length (mm/inch) (C) | 2600/102 |

| Weight (kg/lb.) | 11000/24251 |

| Connection details | |

| Main voltage +/-10% (EU) | 3x400V-50Hz |

| Main voltage +/-10% (US) | 3x460V-60Hz |

| Power kW | 26 |

| Common parameter | |

| Drum speed (rpm) | 0.5 - 8 |

| Program options standard | 30 programs |

| Double jacket | Standard |

| Single jacket | Option |

| Remote access | Option |

Parts & Services

MA12000

)

)

)

)

)

)

)

)

)

)

)

)

)

)