Type 8-35 Press

Bacon Press - Type 8-35

The Danfotech Type 8-35 presses bellies using a die set, which shapes the products into the desired finished form.

The frozen meat is molded in the hydraulically operated press, where it is exposed to three-dimensional pressure to attain uniform shape and quality for maximized slicing yields.

The 8-35 bacon press offers automatic infeed and discharge options with various ancillary systems available.

Maximize slicing yields at optimal temperatures ranging from 14°-25° F (-10° to -4° C) depending on salt content.

The Danfotech 8-35 in numbers:

- Up to 8 cycles per minute

- Automatic and manual operation

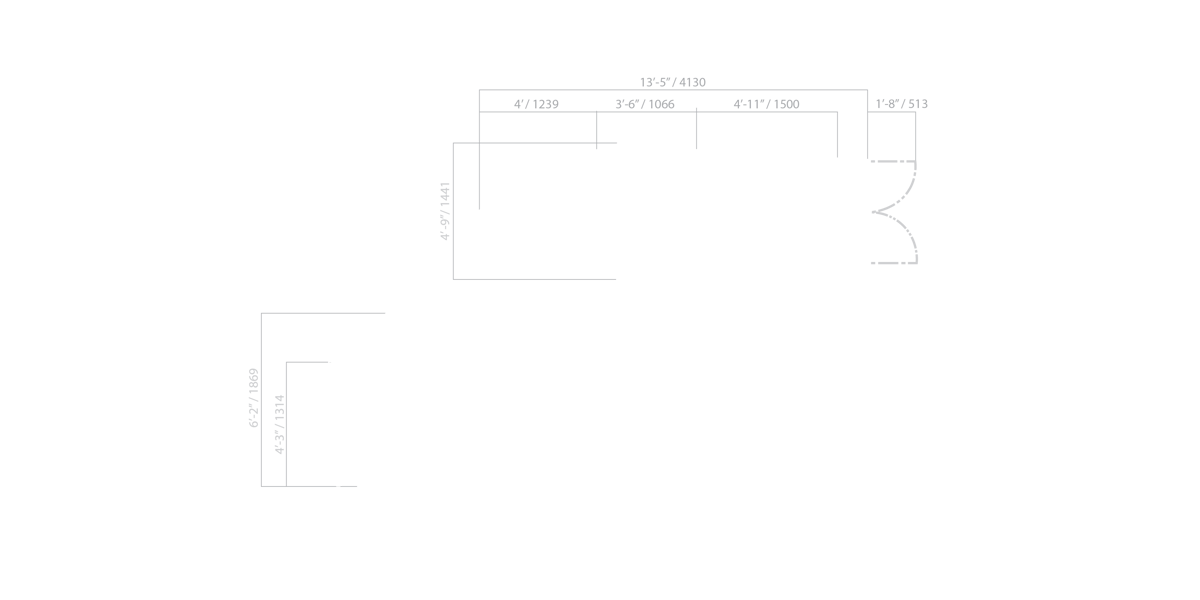

- Press chamber length at 35” x 16” x 4.8”

- Press chamber length at 875mm x 415mm x 120mm

- Quick toolless die change in less than 5-7 min.

- 380V-460V x 3 phase 50Hz or 60 Hz

- 63 Amps

- Air pressure @ 100PSI or 7 bar

Type 8-35 Meat and Bacon Presses

- Presses 8 bellies per minute with a powerful but gentle hydraulic pressing system

- The press cycle establishes product height and width. Pressed length depends on size of belly

- Max die chamber size: 35” x 16” x 4.8” (875 x 415 x 120 mm)

- Automatic programmable lubrication system

- Allen-Bradley controls with color touch screen HMI

- Left or right outfeed available

- USDA accepted and CE approved. Built-in conformity with AMI sanitary equipment design principles.

Contact

Contact

Size specifications

Technical specifications

| Up to cycles per minute | 8 - Depending of manual loading |

| Power | 40 hp / 30 kW |

| Control Voltage | 24 VDC |

| Service Amps | 63 A |

| Cooling Water | 1.6 gal/min. / 6.05 l/min. |

| Water Pressure | 29-87 psi / 2-6 bars |

| Air Pressure | 100 PSI or 7 bars |

Parts & Services

Type 8-35 Press

)

)

)

)