Type 10S Servo Press

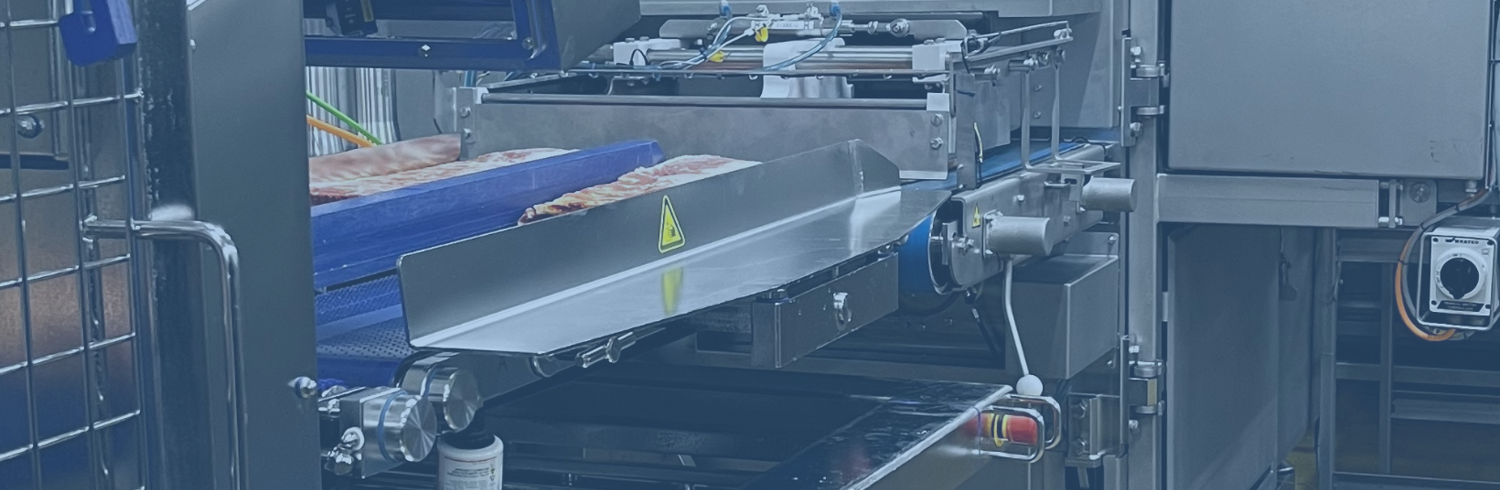

The DANFOTECH Servo-operated Bacon Press is specifically designed to ensure optimally shaped bacon and meat loins, pressed in the 4-directional, 3-dimensional dynamic and flexible chamber using the ShapetecTM press technology.

Setting the stage for optimal slice yield downstream.

The press is equipped with automatic in/out-feed conveyors.

The press is built with a heavy-duty design that is engineered to withstand the impacts of pressing frozen bacon and meat loins for many hours every day over a very long period.

The key focus areas:

- No Water or Hydraulics

- Reduces belly fractures

- Optimum automation ensured

- Largest die chamber in the Industry

- Up to 10 cycles/min. press capacity

- Automatic flex in die-set

- Easy maintenance and operation costs are the lowest in the market.

- Fast and Easy to clean and sanitize

The Danfotech 10S in numbers:

- Up to 10 cycles per minute

- Press chamber length at 35” x 16” x 4.7”

- Press chamber length at 889mm x 406mm x 120mm

- Up to 20mm / .75” automatic flex

- Quick toolless die change in less than 5-7 min.

- 380V-460V x 3 phase 50Hz or 60 Hz

- 80 Amps

- Air pressure @ 100PSI or 7 bar

Type 10S Meat and Bacon Presses

The 10S Servo Press is designed for automatic operation with 4 individual servos controlled by ShapetecTM press technology which secures the perfect compression and automatically flexes the height, based on the individual thickness of the product to be pressed.

Labor-saving automation with custom-built product conveyor handling systems to transport product from freezing/crust freezing through pressing to feed single or multiple slicing/cutting lines. Danfotech can integrate with both new and existing production lines.

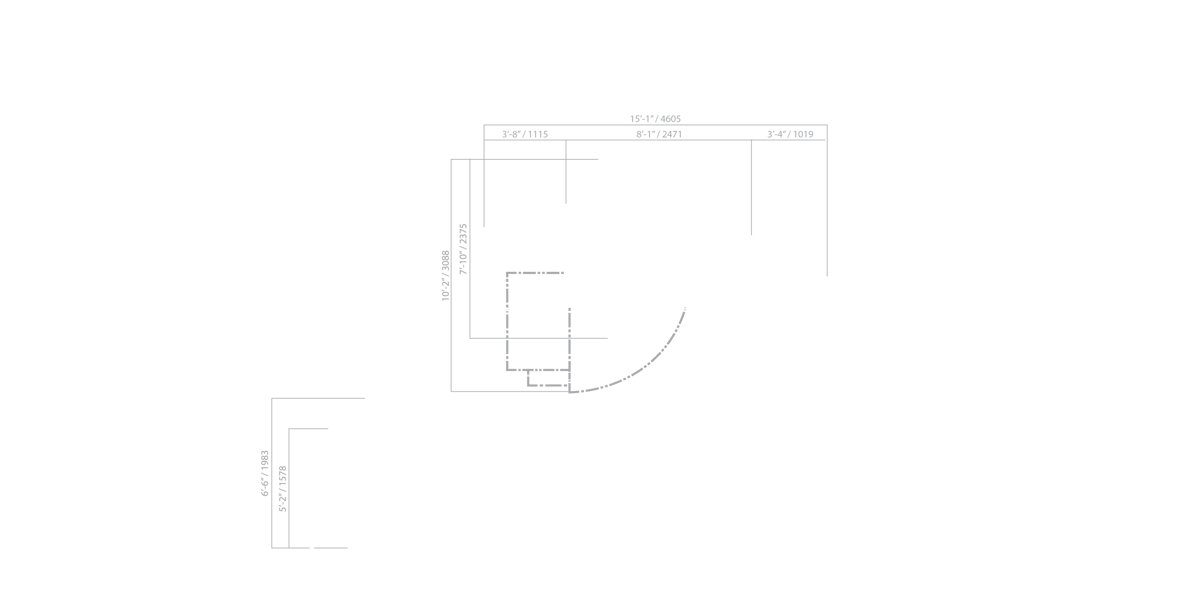

Size specifications

Technical specifications

| Up to cycles per minute | 10 |

| Power | All Servo operated. |

| Control Voltage | 24 VDC |

| Service Amps | 80 A |

| Cooling Water | None |

| Water Pressure | 29-87 psi / 2-6 bars |

| Air Pressure | 100 PSI or 7 bars |

Parts & Services

Type 10S Servo Press

)

)

)

)