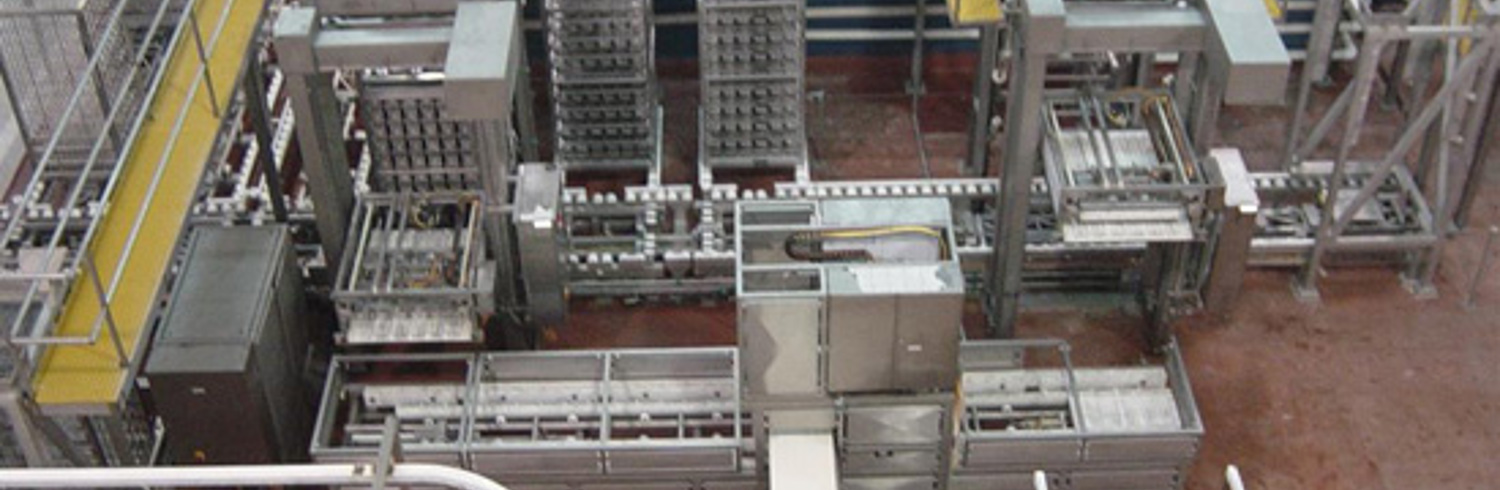

Fully-Automatic Press Tower System

Danfotech's Fully-Automatic Press Tower System is designed to handle products before and after cooking. The system is based on many years of extensive technical experience in handling cooked products around the world. From stand-alone components, such as the demolding and the hydraulic press, to fully automatic production lines with capacities exceeding 250 tons per day, Danfotech can meet the most demanding production goals.

The strength of the fully automatic press tower system for ham production is automation with full process

control. In this flexible production system, meat in calibrated molds is exposed to constant and yet flexible pressure during cooking and cooling. This results in products with high slicing yields. The system offers high product flexibility together with the possibility of various product sizes and shapes. The press towers work in conjunction with water or steam cooking systems.

• Fully automated process

• Highest degree of uniform product with high yield

• Applies pressure during both cooking and cooling

• Low labor rate

• Reduced space requirements

• Large throughput

• Compatible with water or steam cooking.

Parts & Services

Fully-Automatic