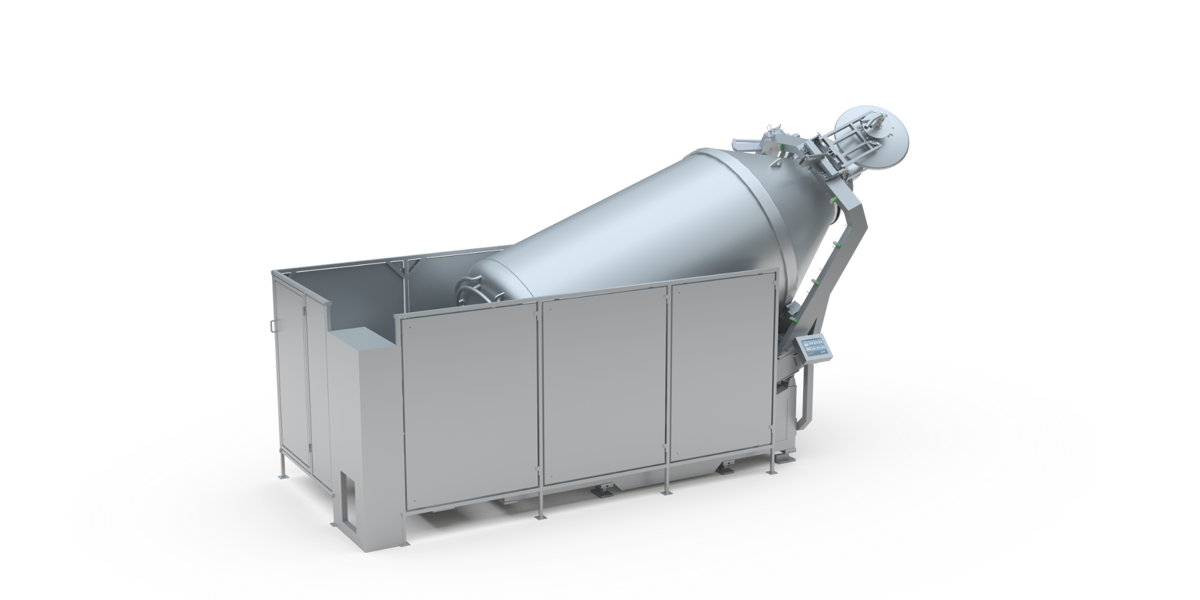

Danfotech Defrosting System Type MA12000

Until now, defrosting frozen meat blocks involved exposing the product to running water, hot air, steam, or microwave tunnels. The results were far from perfect. Compared to traditional defrosting systems methods, the Danfotech Defrost system gives you an additional finished product instead of loss caused by dripping or overheating of the product. The result is a natural-looking defrosted product attained with this revolutionary controlled heating and cooling process.

The Defrost Tumbler can be delivered as a combination of a standard Vacuum tumbler and a tumbler specially designed for defrosting products. The Tumbler can also be offered without the defrosting functionality where cooling is the only possibility.

Product feature:

The automation part is designed with a range of very flexible functions that make it easy to use for many applications like the following:

- Easy operation for developing a new product

- Ideal for normal massaging with continuous vacuum

- Ideal for defrosting products where the expected process time is known

Control Feature:

- Many functions can be operated with semi-automatic functions where limits are still active like the lid can’t be opened if the drum is not in lowered position

- By use of programs, an automated process can easily be operated by only pressing the start

- Have the memory to store 50 individual programs each program has 12 flexible steps

- Can start a program from step 1 but also have the functionality to start from, for example, step 4. This function is very useful for developing new products or can be used if the tumbler has a longer power interruption or similar disruption.

- Easy modification of program steps by removing one selected step or inserting a new empty step

- Fast and easy copying of programs from one number to another number

- Etc. Program has a text description for easy identification of a program when selected for use

- All programs have information about the last time for edit dd/mm-hh:mm

- Temporary correction of running step

| Basic Dimensions (vary with options) | |

| Rotate | xx.x rpm |

| Direction | “SOFT” or “HARD” |

| Vacuum | 0-95 % (95 = full vacuum) |

| Jacket Inlet Temp | xx.x °C |

| Auto operate - program parameters for each step (vary with options) | |

| Step description | “Customised text” |

| Speed | xx.x rpm |

| Vacuum | 0-95 % (95 = full vacuum) |

| Direction | “SOFT” or “HARD” |

| Angle | xx |

| Total Time | xxxx min. If timed step max. time for the actual step |

| O. Temp | “No” or “Yes” Limit function for overtemperature correction |

| Jacket Temp | XX °C inlet temperature set-point for Jacket |

| Work time | xxx min. Active rotate time |

| Pause time | xxx min. Pause of rotation |

We understand that different customers may have varying needs, and we are committed to providing a customized solution to ensure optimal results.

Size specifications

Technical specifications

| Model option | MA8000 |

| Volume (liter/cubic feet) | 12000/424 |

| Degree of admission approx. 50% (kg/lb.) | 6000/13228 |

| Degree of admission approx. 35-40% frozen blocks |

4800/10582 |

| Basic Dimensions (vary with options) | |

| Length (mm/inch) (A) | 5900/232 |

| Length (mm/inch) (B) | 4300/169 |

| Length (mm/inch) (C) | 2600/102 |

| Weight (kg/lb.) | 7000/15433 |

| Connection details | |

| Main voltage +/-10% (EU) | 3x400V-50Hz |

| Main voltage +/-10% (US) | 3x460V-60Hz |

| Power kW | 26 |

| Common parameter | |

| Drum speed (rpm) | 0.5 - 8 |

| Program options standard | 30 programs |

| Double jacket | Standard |

| Remote access | Option |

Parts & Services

MA12000

)

)

)

)

)

)

)

)

)