Hall knew that expanding into the pre-sliced bacon market would require a new level of consistency and efficiency while still maintaining the high standards that had always defined the business. However, slicing unpressed products presented several challenges: inconsistent shapes, higher waste, and more trimming - ultimately affecting both yield and presentation.

When Hall & Roberts expanded into the sliced bacon market, new production demands emerged. Without pressing, inconsistencies in shape led to increased waste and trimming, affecting both yield and presentation. The challenge was to enhance efficiency while maintaining the high standards their customers expected.

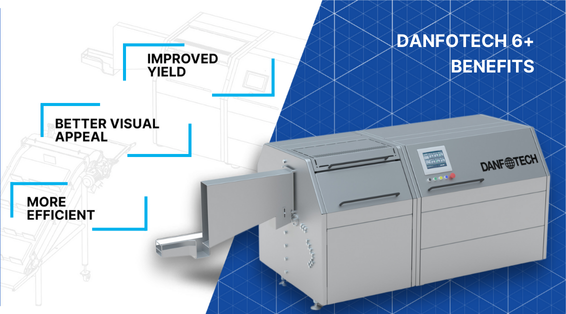

To overcome this, Hall & Roberts turned to Danfotech. By integrating the Type 6+ Press, they improved product uniformity, reduced waste, and increased yield—without compromising on quality. The results were immediate, making production more efficient while ensuring a consistently high standard.

"The improved process resulted in a 6% yield increase..."

At Danfotech, we take pride in delivering solutions that make a real difference for our customers. Hearing how our technology helps businesses improve efficiency and maintain quality is what drives us forward. Feedback like this inspires us to continue innovating and providing the best possible support.

"We could see benefits almost immediately. It was very smooth, and we would not hesitate to recommend Danfotech to other companies."

Anthony Hall

"The Danfotech 6 Plus Press improved our yield, enhanced product presentation, and made our processes more efficient."

Chris Moss-Sutton

With the implementation of the Danfotech Type 6+ Press, Hall & Roberts successfully enhanced their slicing operation, ensuring product uniformity while increasing efficiency. The improved process resulted in a 5-6% yield increase, significantly reducing waste and optimizing slicing performance. By pressing bacon into precise, consistent shapes, the company not only maintained but elevated the product quality their customers expect.

The Danfotech Type 6+ Press is engineered to deliver maximum efficiency in meat processing. It applies controlled pressure to bacon and meat loins, ensuring uniform shapes for optimized slicing and reduced trim loss. Whether handling streaky, back, or middle bacon, the press provides consistent results, making it a highly valuable addition to any production line.

At Danfotech, we are committed to helping meat processors achieve the highest possible standards through innovative technology. The 6+ Press delivers an optimal combination of precision, efficiency, and ease of use, allowing businesses to maximize yield while ensuring superior product presentation. With energy savings of up to 50% compared to traditional hydraulic systems, the press offers a cost-effective, sustainable solution for modern meat processing.

Working with Hall & Roberts has been a great opportunity to support their transition to a more efficient and consistent production process.

If you’d like to learn more, feel free to explore Hall & Roberts or contact Jacob for further details. We’re happy to discuss how Danfotech can support your production needs.